-

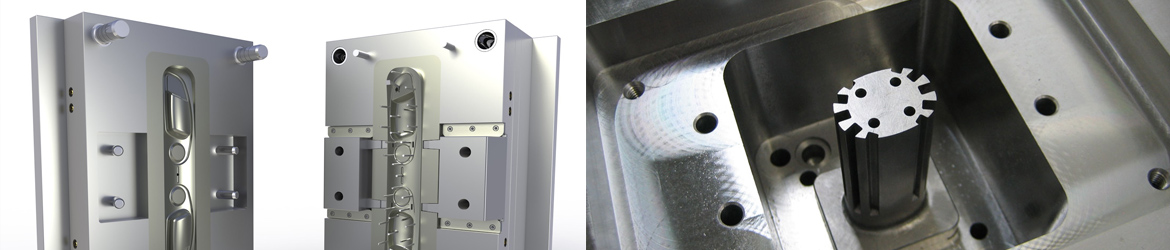

Injection moulds

-

Matrixes

-

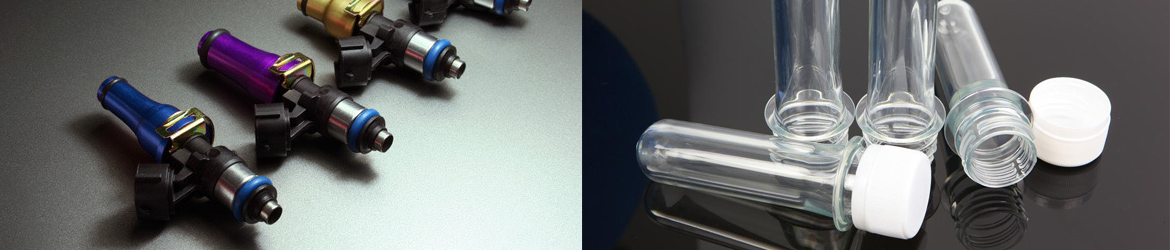

Injection systems

-

Injectors

-

Hot chambers

-

Sliding and rotating components

DLC Mida coating is excellently applied in the field of Plastic Material Moulding because:

-

Thanks to the reduction of friction and to the ceramic effect of the coating, the moulding process is significantly improved because the plastic mass is easily removed.

-

The excellent anti-adherence effect of the coating facilitates the removal of the object avoiding distortion or inaccuracies on the treated parts.

-

The high surface hardness given by the coating preserves the mould from the wear caused by polymers ionized by different fibres, protecting the glossy mirror-like and satin surfaces, while safeguarding the mould from the corrosion derived from the gases ejected during the process of moulding.

-

Various components, parts of machines for injection moulding like ejectors, pushing devices, males, locks, lock push rods are efficiently protected by DLC MIDA coating against oxidation, wear and friction.

-

The DLC coating moreover facilitates the cleaning of the moulds avoiding the use of aggressive methods.

Advantages of MIDA treatment

-

Supplies a high level of protection against wear and corrosion

-

Coating fit for extreme conditions and high speed

-

Strongly counselled for lubricant-free systems

-

Neutral coating for food